- ×

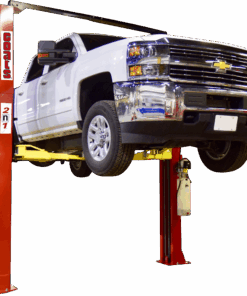

Coats 16K 2N1 Post Lift 1 × $19,374.00

Coats 16K 2N1 Post Lift 1 × $19,374.00

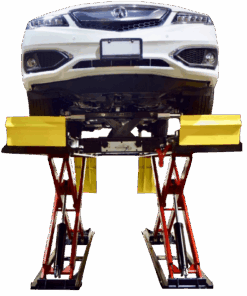

Coats 16K Scissor Lift

$43,098.00

The runway under the rear slip plates is open to prevent water and dirt from collecting. 7/8” slip plate balls are large diameter and raised up from the runway to keep out dirt and contaminants.

SKU: 8KSC16KITP Categories: Coats Lifts, Scissor Lift, Vehicle Lifts Tags: 16K Scissor Lift, COATS, Lift

Coats 16K Scissor Lift

The Coats 16K Scissor Lift is powder-coated and double-baked to protect against structural corrosion and the harshest working environments. By choosing premium components and manufacturing techniques, Coats lifts reduce overall maintenance costs.“Breakout” Assist Cylinder helps raise the lift from a fully lowered position and catches the lift when lowering back down, reducing tension on other components, 16K only. Non-Flex Runways Reinforced double wall “Z” rail runway reduces flex, increasing alignment accuracy and repeatability. Greased fittings ensure all pivot and hinge points are easily maintained and provide a longer life. Heavy Duty Turn Plates: Stainless steel turn plates have Polyethylene liners that are corrosion-resistant and allow for easy turn plate positioning. Floor or Wall Console The electronic and hydraulic-controlled system keeps the lift level at 21 locking positions. Rear Slip Plates Open runway slots allow water and debris through to prevent corrosion. Elevated chrome ball bearings allow slip plates to move freely. Mechanical Locking The floor-mounted rack and pinion mechanical locking system disperses load directly into the floor. Adjustable locking plate positioning ensures precise alignment measurements. Hydraulic Cylinders North American-made Hydraulic Cylinders with spherical bushings keep cylinder alignment constant and the lift level. Sensor Leveling System: Sensor feedback leveling

system ensures your lift stays level. It is strategically located and protected from environmental conditions. The runway under the rear slip plates is open to prevent water and dirt from collecting. 7/8” slip plate balls are large diameter and raised from the runway to keep out dirt and contaminants.

Related products

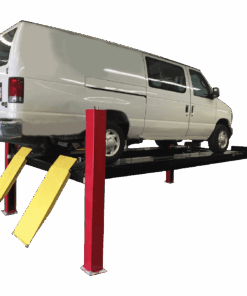

4 Post

$34,888.00 – $36,642.00Price range: $34,888.00 through $36,642.00

This product has multiple variants. The options may be chosen on the product page $18,040.00

This product has multiple variants. The options may be chosen on the product page Coats

$10,195.00 – $13,707.00Price range: $10,195.00 through $13,707.00

This product has multiple variants. The options may be chosen on the product page 4 Post

$40,321.00 – $42,501.00Price range: $40,321.00 through $42,501.00

This product has multiple variants. The options may be chosen on the product page Coats

$13,295.00 – $15,857.00Price range: $13,295.00 through $15,857.00

This product has multiple variants. The options may be chosen on the product page